Introduction:

Based on research, the clothing industry was worth around $1.5 trillion in 2020, and the numbers were forecasted to grow to $2.25 trillion by 2025. In this vast, competitive, fast-paced, large-scale market, the brands, and industry giants feel a vital need for supply chain management. The supply chain management makes sure the brand goes towards success in the fashion season. Moreover, the supply chain also increases the ability to quickly pivot the latest trends and trending styles.

When we are talking about the clothing industry, there are several moving parts that we need to manage. Supply chain management helps control the flow of these goods and all the services required to run your business efficiently.

In today’s picture, it depends on how well you can manage the flow between these moving parts, as this is the critical part that can make or break your business, regardless of which type of business you are doing.

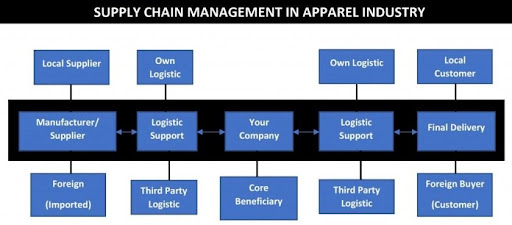

Supply Chain Management in Apparel Industry

Effective supply chain management has become a must in the clothing business. This supply chain management is essential for all who source the product from elsewhere in the clothing business.

As you know, fashion changes every other day, and limitless options in huge variety of products create complex supply chains. This brings out the different facets of the supply chain. SCM is no less than a critical factor in the apparel business. That’s why it is crucial to understand each facet of supply chain management.

The Supply Chain’s ability to Manage Resources

It’s a process of moving and managing the resources from one place to another, from one party to another, from one section to the next, from one department to the next, and it can be anything. It is essential to ensure the movement of the resource so that the right product comes to availability at the right time in the right place with enough quantity.

The Idea of supply chain management is broad, and there are certain things that you need to consider the supply chain management.

The crucial thing and benefit of setting up a supply chain management are locating the required resources at minimum costs. The management of moving goods and finding the services is linked with logistics. This is why logistics is another critical term in the clothing business supply chain management. In short, supply chain management comes handy in every stage of manufacturing.

Docshipper Tip: DocShipper offers international freight forwarding services but also a procurement services in Asia. With this comprehensive offer, we can accompany you through all stages of the supply chain without you having to intervene or stress yourself. For more information or to request a free quote in less than 24 hours, please fill out this simple form.

Breaking Down the Supply Chain Process in Clothing Industry

The Apparel industry is labor-intensive, with around tens of millions of labors associated with it daily. The supply chain management process refers to the tracing and locating of each step of the clothes or resources in the clothing manufacturing. The process starts with sourcing the fabric from the garments factories where the clothes fabric is prepared. Next comes the distribution process, which means supplying the material to the consumers.

It’s a lengthy process. Here is a breakdown of supply chain activities:

Designing

The design is the initial stage of the supply chain management and the clothing process, where the trims, fabrics, silhouettes, and finishes are established. If we look all around the globe, we will see that different trends are changing quickly. The clothing industry has become a fast-fashion world, responsible for many clothing lines.

Each year, around 92 million tons of garment is produced, i.e., equal to a rubbish truck filled with clothes, dumped over land every second. Discarding old-fashioned garments has become a common practice.

Unlike fast fashion, slow fashion looks thoroughly at each phase of the supply chain management of clothing. Here the designers or the manufacturer consider the material and all the impact on production till the consumer stage. The supply chain helps minimize the adverse effects on the environment around them.

Many brands are trying to turn the wheel in the back direction, turning away from the rhythm of fast fashion and more likely to adopt a sustainable and long-lasting approach. Moreover, a number of brands embrace the cradle-to-cradle design framework, and the cradle-to-cradle framework must fit one of two cycles.

Industrial Cycle: Where the recycling loop is closed, recycling the non-degradable material.

Biological Cycle: here, the recycling loop is closed by returning the products harmlessly to nature.

Production Of Materials

The production phase includes a complex process of creating, gathering the raw material, turning it into the fiber, then moving the fabric to the next phase, which might be dyeing, washing, screen printing, and finishing. The textile production phase is a significant contributor and responsible for environmental pollution, as the toxic gas emission contaminates the fresh air and water.

One of the clothing industry’s significant drawbacks is that many chemicals turn garments into fabrics. These chemicals are released into the water, contaminating and damaging the water life. Moreover, this water is also used for irrigation and agriculture purposes.

The sea or river water is essential because the central element in the clothing industry, cotton, is cultivated using fresh water. It requires thousands of liters of water to produce cotton for a single piece of T-shirt.

Another drawback primarily found in the clothing industry is the forced labor, used mainly in the cotton picking, spinning, and weaving level work. Uzbekistan is commonplace and known for child labor. But the fantastic news is that clothing industry circumstances are improving, and new standards are being set to ensure fair trade.

DocShipper Advice

DocShipper Advice : If you want to start your own clothing business by importing or exporting clothing from other countries, DocShipper can help you find a reliable supplier, but also take care of the customs clearance and international freight shipping. Contact us to know more.

Production of Clothes

This is a primary phase in the cloth manufacturing process. The material produced in the previous step is used for cutting, sewing, and finishing the garment. In the last 30 years, the production of clothes is shifted to the Asia region.

As the vast brands are developed and coming into different countries, this has greeted millions of workers with the hope of getting free. Around 21 million people all around the globe are facing forced labor in the clothing industry. Of which half, 11.4 million women and girls. Here the violations and other harassment cases are expected.

Distribution & Retail

After the clothes are manufactured, they are transported to the retailers and then further transported to the consumers, or consumers buy them from the retailers. This phase also includes a drawback, as these clothes are transported to the retailers and distributors, which increases the air pollution by producing the carbon emission.

The negative factor of this type of air pollution is that it is inevitable. Only brands and major companies operating in the clothing industry can take a step to minimize this effect.

As we told you above, most manufacturing has switched to aboard or in Asia, so international shipping is the solution here. It’s a lengthy and complex topic. No matter what type of product we pick, there are significant chances that that product has already travelled to different parts of the world, and this is how that product contributes to bringing the pollution to the level it is now.

Reaching to the consumers

The consumers are the targeted group where the finished product is aimed to be delivered. The supply chain management at the consumer level compromises and faces numerous issues and hassles. Here an effective supply chain management strategy comes in handy with backup strategies to cover the losses.

However, if we talk about the impacts on consumer-level with respect to pollution, it comes from laundering the fabrics, not growing, and processing and producing the materials. Unfortunately, the rate of textile recovery by recycling is low, despite being 100% usable or recyclable.

Strategies for Managing the Supply Chain

Like the clothing and fashion industry is huge, there are a number of strategies for the supply chain. Here are a couple of methods that brands and companies use.

Pull Supply Chain Management

The pull strategy is a practice of waiting for the consumer demands to rise and then forecasting them. Here, the manufacturers will only create the products when they know consumers will buy them. Or we can also say that end-users and consumers face retailers and ask for their demands, then retailers manage the supply chain or source the consumer’s demand.

It’s a good practice that helps in reducing the risk of inventory becoming overstocked and helps in managing the inventory.

Push Supply Chain

In Push Supply chain management, the strategy is used by forecasting the market and then making predictions in the supply chain. The designers or manufacturers produce the clothing pieces and styles by analyzing the upcoming demands.

For example, people are more likely to purchase summer outfits, so Swimwear manufacturers start marketing their brand, demand products, and push them into the market and retail stores. Likewise, warm clothes appear on the shelf when the cold weather starts.

Hybrid Supply Chain Management

When both pull and push methods are combined, these are known as hybrid supply chain management. This method helps the companies and brands to save inventory costs and also helps in reducing the unpredictive demands from the consumer end.

The hybrid supply chain management is beneficial for the textile manufacturers in creating the latest designs and garments products. The supply chain starts to work as a push system, while the demands and needs of the new products pull all these materials into the garment production phase.

DocShipper Tip

DocShipper Advice : Docshipper handles all stages of the supply chain to help you save money and give you more time to run your business. You can contact us anytime or call us if you ever need help or a free quote.

4 Key Benefits of Supply Chain Management

So, you might think that supply chain management is a great tool that helps increase productivity and improves organizational cohesiveness. Moreover, there are a number of benefits of using supply chain management.

Minimizing the Inventory Costs

In the fashion industry, brands work with a diverse number of suppliers, and here supply chain can minimize the costs effectively. Before committing to new orders or bulk manufacturing of their product, the brand expects a sample product from them and quotes. Another advantage is that by effective forecasting, the retailers order the amount according to market needs and can be safe from inventory management hassles.

Flexibility In Operational And Organization

To be competitive and stand firm in the market, you need to be precise, flexible, and, most importantly, updated with customers’ requirements. The brands are linked with the designers and manufacturers to create new and latest designs, which gives them the flexibility to source the clothes.

These manufacturers are linked with many diverse suppliers and have networks with the key suppliers that help the brand and companies to source the materials more effectively.

Resource management

Some important elements to consumers are ethical supply, sustainability, and transparency. Better and effective supply chain management leads to better resource management. How the raw material goes in and out, the flow of goods is handled by logistics to adopt more sustainable practices.

Increase the productivity

When working with diverse suppliers, managing all things at once becomes a little complicated. Here the brand and companies need to ensure better communication and collaboration with all partners and suppliers is effective and helps the brand produce and source the products in all circumstances.

When the suppliers and brands have friendly relations with the suppliers and manufacturers, they are less likely to face trouble, hassles, and disruptions along the process. With an effective supply chain management strategy, brands and companies can discover potential concerns, ensuring a good and healthy relationship between both.

DocShipper Info

DocShipper info: Docshipper is here to help you create a good relationship with your suppliers and partners. Our multilingual sourcing Agents can be in direct contact with the suppliers and handle the communication on behalf of their client. So, if you are interested, you can contact them by filling out this simple form!

Wrapping up

So, you see, there are a number of challenges in the clothing industry’s supply chain management, but along with the problems, there are strategies to cope with the issues. In recent years, there has been an increasing popular demand for shorter shipping times from the end consumers.

Here an effective supply chain would come in handy by doing the road map optimization or by delivering through the express delivery services. It is advised to revise the supply chain management process and always look for ways by which we could improve the supply chain management and make it more efficient.

FAQ | Supply Chain Management In The Fashion Industry

The supply chain management process in the clothing industry refers to the stages of clothing manufacturing. It includes everything from sourcing the raw material to factories, to the distribution of finished clothes to the end-users.

An effective supply chain management process and strategies are essential in the clothing industry. Here are a couple of things that supply chain management takes care of: lower inventory, higher profits, shorter lead times, materials sources, and the demand and supply circle.

The benefits of supply chain management are : greater productivity, higher profits, inventory management, lower inventory costs, building customer trust, and ensuring customer loyalty.

Read More

You might be interested in these articles

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us