Introduction

In 2025, putting AI in supply chain is no longer just a competitive advantage—it’s become an essential survival tool for logistics providers and supply chain operators worldwide.

The global AI in logistics market has exploded to $20.8 billion in 2025, representing a staggering 45.6% CAGR from 2020, according to the latest McKinsey Global Institute report.

This revolutionary technology is fundamentally reshaping how goods move across the globe, with 78% of supply chain leaders reporting significant operational improvements after implementing AI-powered logistics solutions.

As customer expectations for same-day deliveries, real-time tracking, and personalized service continue to rise, organizations that fail to leverage AI capabilities find themselves increasingly unable to compete. In an era where 65% of logistics costs are tied to last-mile delivery and inventory inefficiencies, supply chain automation driven by artificial intelligence offers a pathway to not just survival but remarkable growth.

DocShipper has positioned itself at the cutting edge of this transformation, integrating AI across our entire operations, from sourcing to delivery. Our AI-powered platform is not just a tool, but a comprehensive approach to reimagining global logistics.

This comprehensive guide explores how AI is revolutionizing the logistics and supply chain landscape in 2025, and how forward-thinking companies can leverage these technologies to thrive in an increasingly complex global marketplace.

Understanding How AI is Changing Logistics & Supply Chain

The integration of artificial intelligence shows exactly how AI is changing logistics & supply chain operations from experimental to mission-critical.

To appreciate the full scope of this transformation, it’s essential to understand the core technologies driving change and how they’re reshaping traditional systems by integrating AI in supply chain.

AI Technologies Changing Logistics & Supply Chain : Real cases

AI-powered logistics platforms are delivering measurable impact across the industry, with real-world results that demonstrate the technology’s transformative potential in logistics operations:

- Maersk’s AI-driven maritime logistics has decreased vessel downtime by 30% through predictive maintenance, saving over $300 million annually and reducing carbon emissions by 1.5 million tons. Their AI systems analyze over 2 billion data points daily from 700+ vessels, predicting equipment failures up to 3 weeks in advance with 85% accuracy.

- Amazon’s warehouse robotics program now includes over 520,000 AI-powered robots working alongside humans, cutting fulfillment costs by 20% while processing 40% more orders per hour. Their computer vision systems have improved picking accuracy to 99.8%, virtually eliminating returns due to incorrect items.

- DHL‘s AI-powered forecasting platform has reduced delivery times by 25% across 220 countries while improving prediction accuracy to 95%. Their “Smart Trucks” utilize machine learning algorithms to dynamically reroute deliveries based on traffic, weather, and new pickup requests, saving 10 million delivery miles annually.

- Walmart has deployed AI inventory management systems across 4,700 stores, reducing inventory costs by $1.5 billion annually while maintaining 99.2% in-stock rates. Their demand forecasting algorithms analyze 200+ variables per product to optimize replenishment.

- UPS‘s ORION route optimization system uses AI to calculate optimal delivery paths, processing 30,000 route optimizations per minute and saving 38 million liters of fuel annually. The system prevents approximately 100,000 metric tons of carbon dioxide emissions each year.

- Mid-sized logistics provider XPO has embraced AI-powered freight matching, reducing transportation costs by 15% and allowing them to compete effectively with industry giants. Their AI platform matches 99.7% of loads automatically without human intervention.

These industry leaders demonstrate how AI is changing logistics & supply chain management concretely in 2025 through measurable results that directly impact the bottom line. The technology has moved far beyond theoretical benefits to provide documented ROI across diverse logistics operations.

The Evolution: How AI is Changing Logistics & Supply Chain ?

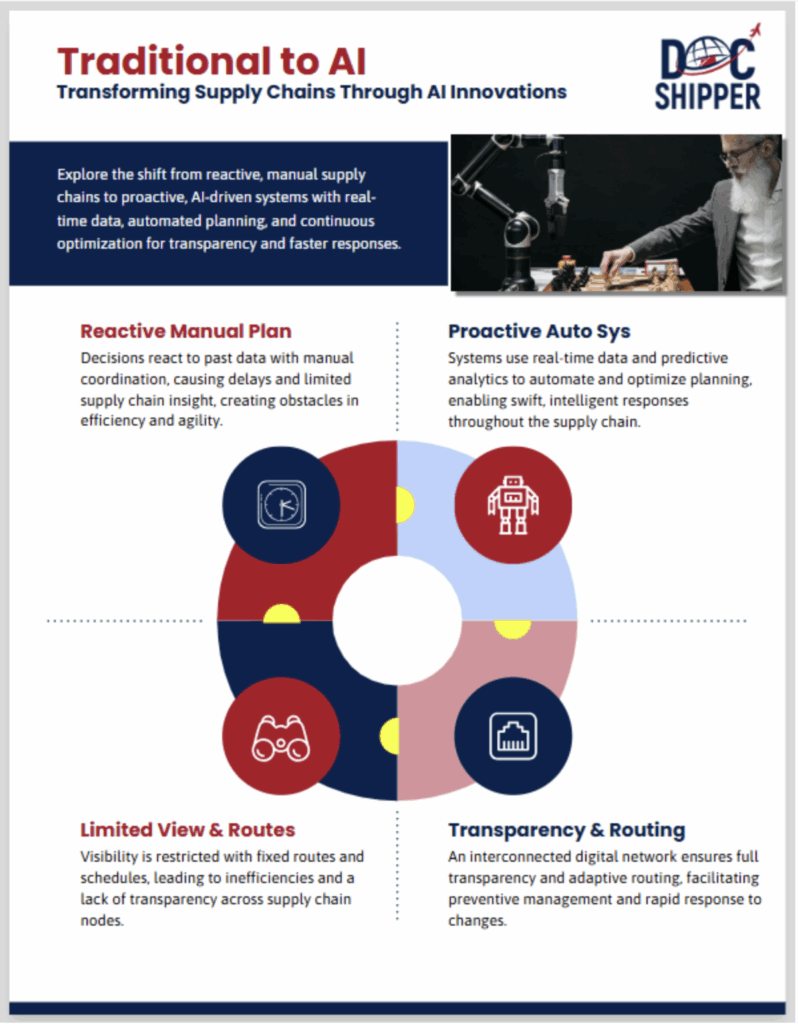

The journey from traditional to AI-driven supply chains represents a fundamental paradigm shift in how goods move from manufacturers to consumers. So let’s understand it better via this comparison table:

Traditional Supply Chain | AI-Driven Supply Chain |

Reactive decision-making based on historical data | Proactive decision-making using real-time data and predictive analytics |

Manual planning and coordination | Automated planning with continuous optimization |

Limited visibility across supply chain nodes | End-to-end transparency and traceability |

Fixed, predefined routes and schedules | Dynamic routing and scheduling that adapts to conditions |

Isolated systems with manual data transfer | Interconnected digital ecosystem with seamless data flow |

Periodic forecasting with significant human input | Continuous forecasting with machine learning algorithms |

Response time measured in days or weeks | Response time measured in minutes or hours |

Exception-based management | Preventive management through early detection |

This evolution has accelerated dramatically in recent years, with 67% of supply chain executives reporting that their organizations have fully or partially automated key processes using AI by 2025, according to Gartner’s latest Supply Chain Technology User Survey.

Building on this momentum, the shift from traditional to AI-powered supply chains is not just a technological upgrade-it’s a transformation in operational mindset and capability.

To visualize these changes, explore the infographic below, which highlights how industry trends are rapidly moving from manual, reactive approaches to more automated, data-driven, and intelligent logistics and supply chain methods.

DocShipper Advice

Ready to Modernize Your Logistics? Is your current system holding you back? Well know that DocShipper’s AI Platform Offers:

- Real-time tracking

- 30% faster processing

- 99.5% accuracy

- Personalized logistics solutions

Schedule Your Free AI Logistics Consultation and let us upgrade your logistics game.

Digital Twins disrupting the old fashion supply chain and logistics operations

Digital twins now replicate entire supply networks in virtual environments, allowing companies to simulate changes and anticipate disruptions before they occur.

Meanwhile, generative AI systems are creating optimal transportation routes, warehouse layouts, and packaging designs that human planners could never conceive.

DocShipper has embraced the AI revolution by placing intelligent algorithms at the core of our logistics operations. Our proprietary AI platform analyzes 2,000+ global shipping routes daily, enabling us to offer clients the fastest, most cost-effective logistics solutions.

DocShipper info

Through AI implementation, we’ve increased our operational capacity by 30% in 2025 allowing our specialists to handle three times more client requests than traditional methods would permit. Learn how our AI-enhanced services can transform your logistics operations, reach out to our specialists to guide you through.

Key Benefits: How AI is Changing Logistics & Supply Chain

The strategic implementation of artificial intelligence across supply chain operations delivers multifaceted benefits that extend far beyond simple cost reduction. Organizations embracing AI are experiencing transformative improvements in operational efficiency, forecasting accuracy, and risk management capabilities.

AI upgrading Logistics & Supply Chain Efficiency and Cost Reduction

AI is Changing Logistics & Supply Chain by its technologies that are driving unprecedented operational improvements that translate directly to bottom-line benefits.

Predictive Maintenance and Resource Optimization

AI-driven predictive maintenance represents one of the most impactful applications in logistics operations, delivering substantial cost savings while maximizing asset utilization:

- Port of Rotterdam’s AI system monitors 42 million vessel movements annually, predicting maintenance needs for 100,000+ assets with 95% accuracy. This has reduced unexpected downtime by 20% and extended equipment lifespan by 25%, saving €31 million annually.

- FedEx’s predictive maintenance platform analyzes data from 35,000+ vehicles, reducing fleet maintenance costs by $11 million annually and cutting vehicle downtime by 22%. Their AI algorithms identify potential failures up to 78 hours before they occur.

- Kuehne+Nagel’s AI-powered resource allocation optimizes workforce scheduling across 1,300 locations, resulting in 15% labor cost reduction while handling 20% more shipments. Their system processes 1.5 million scheduling scenarios daily to find optimal staffing patterns.

These systems continuously monitor equipment health through IoT sensors, analyze historical failure patterns, and optimize maintenance schedules to prevent costly breakdowns while maximizing resource utilization.

DocShipper Tips

Why DocShipper Stands Out in AI-Powered Logistics?

Because we are the agile alternative to tech giants !

While industry behemoths like Amazon and Maersk deploy massive, rigid AI systems, DocShipper offers:

- Personalized AI Solutions: Custom-tailored to your specific logistics needs

- Flexible Implementation: Scalable AI that adapts to your business

- Comprehensive Logistics Ecosystem:

– Integrated sourcing

– Intelligent freight management

– Automated customs processing

– Smart client dashboard

Our AI isn’t just a tool—it’s a strategic partner that grows with your business.

Explore Our AI-Powered Logistics Solutions, talk to a DocShipper expert now!

Automated Decision-Making and Process Streamlining

Supply chain automation through AI has advanced to handle increasingly complex decision processes:

- Microsoft’s global logistics network uses AI to automate fulfillment planning for hardware shipments. Their system generates detailed plans covering inventory allocation, carrier selection, and scheduling across 40+ distribution centers, reducing planning time from 4 days to 30 minutes while improving accuracy by 24%.

- Nike’s AI-driven production and distribution system automatically allocates manufacturing capacity across 500+ facilities and adjusts distribution plans for 120,000+ SKUs daily, reducing lead times by 50% while maintaining 99.7% fulfillment accuracy.

- Siemens’ AI procurement platform automatically evaluates 15,000+ suppliers against 200+ criteria, negotiates prices within approved parameters, and executes routine orders without human intervention. This has reduced procurement cycle times by 60% and generated 11% cost savings.

By delegating routine decisions to AI systems, these companies have freed human experts to focus on strategic planning and exception handling, dramatically improving both efficiency and effectiveness.

Real-Time Analysis and Response Capabilities

AI is changing logistics & supply chain by using modern AI systems that enable organizations to process massive data volumes instantaneously and respond to changing conditions with unprecedented speed:

- Target’s supply chain AI platform monitors 1,900+ stores in real-time, processing 4.5 million data points hourly to detect inventory anomalies. This capability has reduced out-of-stock incidents by 40% and cut response time to supply disruptions from 2-3 days to under 4 hours.

- DB Schenker deployed AI-powered control towers that monitor 13 million shipments daily across 2,000+ locations. Their system detects disruptions within 3 minutes and automatically reroutes affected shipments, reducing delay incidents by 35% and saving €45 million annually in expedited shipping costs.

- Home Depot’s AI demand sensing technology analyzes 160 terabytes of daily transaction data, enabling real-time inventory adjustments. This has improved in-stock availability by 15% while reducing excess inventory costs by $1.2 billion annually.

These real-time capabilities ensure that organizations maintain service levels despite disruptions, dynamically reallocating resources to address emerging challenges before they impact customers.

AI is Changing Logistics & Supply Chain Forecasting and Demand Planning

Predictive analytics has revolutionized how companies anticipate market needs and prepare their operations accordingly. AI-powered forecasting systems now incorporate a vast array of both structured and unstructured data to deliver unprecedented accuracy.

Advanced Predictive Analytics

Today’s AI forecasting systems extend far beyond traditional statistical methods:

- Unilever’s AI demand forecasting platform integrates 26 external data sources including social media sentiment, weather patterns, and local events.. This is a real example of AI-powered logistics platforms in predicting market needs. IT has improved forecast accuracy from 67% to 92% on a SKU-location level, reducing excess inventory by €300 million while maintaining 99.1% service levels.

- Coca-Cola’s AI system processes 600+ variables per product-market combination, predicting demand fluctuations with 85% accuracy up to 12 weeks in advance. The company has reduced forecast error by 30% and lowered safety stock requirements by €250 million globally.

- Lenovo’s global supply chain AI platform analyzes geopolitical news, currency fluctuations, and semiconductor industry trends to anticipate supply disruptions. Their early detection system identified the 2021 chip shortage 4 weeks before it impacted competitors, allowing them to secure critical components and gain 2.3% market share.

These systems continuously learn from outcomes, refining their models to improve prediction accuracy over time, which creates a virtuous cycle of increasingly precise forecasts.

Dynamic Inventory Management

AI is changing logistics & supply chain and has transformed inventory management from a periodic balancing act to a continuous optimization process:

- Zara’s AI inventory management platform analyzes 300+ million transactions weekly to optimize stock levels across 7,500 stores. The system adjusts inventory 3 times daily based on real-time sales, reducing excess inventory by 20% while maintaining 98% product availability.

- Samsung’s global inventory AI manages 85,000+ SKUs across 200+ distribution centers, dynamically calculating optimal inventory levels based on forecast reliability, lead time variability, and sales volatility. This has reduced overall inventory by $1.2 billion while improving perfect order fulfillment by 15%.

- Best Buy’s dynamic allocation system uses machine learning in logistic to continuously rebalance inventory across 1,000+ stores and 5 e-commerce fulfillment centers. Their AI redistributes overstock items to high-demand locations daily, reducing markdowns by 30% and saving $180 million annually.

These AI-powered systems have transformed inventory from a necessary cost center to a strategic asset that enhances both capital efficiency and customer satisfaction.

Market Trend Identification

Advanced AI algorithms excel at identifying emerging patterns that human analysts might miss:

- P&G’s AI market sensing platform analyzes 4 billion social media posts daily alongside 300+ traditional data sources to identify emerging consumer trends. The system detected the hand sanitizer shortage 8 days before traditional analytics, allowing P&G to increase production by 45% ahead of competitors.

- IKEA’s trend detection AI monitors 75 million monthly customer interactions across digital and physical channels. The system identified a 22% increase in home office furniture interest two weeks before sales surged during the pandemic, enabling IKEA to redistribute inventory and capture €400 million in additional revenue.

- L’Oréal’s AI trend forecasting tool analyzes 6 million beauty-related social media posts daily to predict product preferences up to 4 months in advance with 87% accuracy. This capability has reduced new product development time by 30% and increased successful product launches by 42%.

By identifying emerging trends earlier than human analysts could, these AI systems enable companies to adapt their operations proactively rather than reactively.

Risk Management and Resilience

In an era of increasing supply chain volatility, AI offers powerful tools for anticipating, mitigating, and responding to disruptions of all kinds.

Modern AI systems provide early warning of potential supply chain disruptions:

- Johnson & Johnson’s risk detection AI monitors 27,000+ suppliers across 100+ countries, analyzing 10,000+ risk signals daily including news events, financial indicators, and natural disasters. The system provided early warning of 85% of major supply disruptions in 2024, with an average lead time of 7 days before impacts materialized.

- Toyota’s supply chain risk AI monitors 175,000+ tier-1 through tier-3 suppliers, detecting potential disruptions with 91% accuracy. During recent flooding in Southeast Asia, their system identified at-risk components 11 days before physical impacts, allowing Toyota to secure alternate sources and avoid $280 million in lost production.

- Intel’s AI-powered fraud detection system analyzes 3 million daily procurement transactions, identifying suspicious patterns with 96% accuracy. The system has prevented $47 million in procurement fraud annually and detected compliance violations 35 days earlier than manual auditing.

Note : AI Risk Management in Logistics: Anticipating and Mitigating Challenges

Modern AI risk management in logistics goes beyond traditional approaches, offering:

– Predictive disruption detection

– Comprehensive supply chain vulnerability assessment

– Real-time risk monitoring and mitigation strategies

These capabilities ensure that companies can respond to emerging threats before they cascade into major disruptions, preserving business continuity and customer service levels.

Scenario Planning and Simulation

Digital twins and AI simulation tools enable organizations to test mitigation strategies in virtual environments:

- Procter & Gamble’s supply chain digital twin simulates 3,500+ manufacturing facilities, 600+ distribution centers, and 100,000+ shipping lanes. During the 2023 Suez Canal blockage, P&G’s AI simulated 15,000+ rerouting scenarios in 45 minutes, identifying optimal alternatives that limited disruption costs to $18 million versus an industry average of $42 million.

- Volkswagen uses AI scenario planning to simulate complex “what-if” situations across their global supply network. When semiconductor shortages threatened production, their system evaluated 27,000+ allocation scenarios across 120+ vehicle models, optimizing limited chip supplies to prioritize high-margin vehicles and minimizing profit impact by €1.3 billion.

- Nestlé’s AI supply chain simulator evaluated the impact of potential CO2 shortages on their beverage production, testing 12,000+ mitigation strategies. The simulation identified an optimal approach combining temporary reformulation and production reallocation that maintained 96% of planned output despite a 40% reduction in CO2 availability.

These simulation capabilities allow organizations to develop and test mitigation strategies before disruptions occur, significantly enhancing their response effectiveness when real crises emerge.

Supply Chain Vulnerability Assessment

AI-powered risk assessment tools provide comprehensive visibility into supply chain vulnerabilities:

- Apple‘s supplier risk AI evaluates 350+ factors across 2,000+ direct suppliers, generating vulnerability scores that are updated daily. Their system identified critical dependencies in power management chips 7 months before industry-wide shortages emerged, allowing Apple to secure long-term contracts and maintain 98% component availability while competitors struggled.

- Adidas‘ supply chain vulnerability AI analyzes network dependencies across 500+ suppliers and 300+ logistics providers. The system identified that 47% of their athletic footwear relied on materials passing through three vulnerable ports, leading to a strategic redistribution that reduced this concentration to 23% and prevented $135 million in potential disruption costs during recent port strikes.

- Bristol Myers Squibb’s pharmaceutical supply chain AI maps 16,000+ inputs across 120+ critical medications, identifying single points of failure. This analysis revealed that 38% of their portfolio had dangerous dependencies on specific API suppliers, leading to a strategic sourcing initiative that reduced critical vulnerabilities by 65%.

By providing visibility into hidden vulnerabilities, these AI tools enable strategic improvements that enhance supply chain resilience before disruptions occur.

DocShipper Advice

Struggling with supply chain disruptions? DocShipper’s AI-powered risk assessment tools provide real-time monitoring of potential threats to your global logistics operations.

Our predictive systems identified 78% of major shipping disruptions in 2024 an average of 9 days before they impacted operations, giving our clients the critical time needed to implement contingency plans.Contact our risk experts today !

Challenges and Limitations of AI Adoption in Logistics and Supply Chain

Despite its transformative potential, AI implementation in logistics and supply chain operations presents significant challenges that organizations must navigate carefully.

1. Implementation Costs and ROI Concerns

The financial barriers to AI adoption remain substantial, particularly for smaller organizations:

- The average enterprise-grade AI-powered logistics platform costs between $500,000 and $2.5 million to implement, with ongoing maintenance representing 15-20% of initial costs annually.

- According to Gartner, 62% of supply chain AI initiatives exceed their budgets by an average of 45%, largely due to unforeseen data preparation requirements and integration complexities.

- While AI investments show compelling ROI—with McKinsey reporting median returns of 3.5x investment over three years—the upfront costs remain prohibitive for many. Only 28% of mid-sized logistics providers ($10M-$100M annual revenue) have implemented comprehensive AI solutions, compared to 73% of large enterprises.

- Cloud-based AI solutions with consumption-based pricing models have reduced entry barriers, allowing organizations to start with targeted applications requiring $50,000-$150,000 initial investment rather than comprehensive transformations.

2. Data Quality and Integration Issues

AI is changing logistics & supply chain, as a result AI effectiveness depends entirely on the quality and accessibility of underlying data:

- A 2024 MIT supply chain study found that the average logistics organization utilizes only 23% of its available data for AI applications, with the remainder trapped in legacy systems or suffering from quality issues.

- Data consistency represents a major challenge, with transportation management systems and warehouse management systems speaking different “languages.” Companies report spending 60-70% of AI project budgets on data preparation and integration rather than on AI algorithms themselves.

- Master data management issues plague 76% of supply chain organizations, with duplicate records, inconsistent formats, and missing fields undermining AI accuracy. Companies with formal data governance programs report 3.2x higher success rates for AI initiatives.

- Integration between operational technology (OT) and information technology (IT) remains challenging, with only 34% of organizations reporting seamless data flow between physical equipment and AI decision systems.

3. Workforce Adaptation and Change Manageme

The human element often determines AI implementation success or failure:

- According to a 2024 Deloitte survey, 72% of logistics AI implementations that failed cited workforce resistance rather than technical issues as the primary cause.

- Skill gaps present major obstacles, with 68% of supply chain organizations reporting difficulty recruiting qualified data scientists and AI specialists. The shortage of talent has driven a 35% premium on salaries for professionals with both supply chain domain expertise and AI technical skills.

- Effective change management strategies have proven crucial, with companies that invested at least 15% of their AI project budgets in training and change management reporting 2.8x higher adoption rates and 3.5x higher ROI.

- Collaborative approaches to AI implementation—where operational experts work alongside technical specialists—show 65% higher success rates than technology-led approaches that fail to incorporate domain expertise.

4. Ethical and Privacy Considerations

As AI is changing logistics & supply chain, and it becomes more pervasive in supply chains, ethical concerns demand careful attention:

- Transparency issues arise when AI makes decisions that impact suppliers and customers. According to a 2025 MIT study, only 23% of logistics AI systems provided sufficient explanation of their decision processes to satisfy stakeholder concerns.

- Data privacy regulations like GDPR and CCPA impact how supply chain data can be used for AI training, with cross-border data transfers creating particular complexity. Companies operating global supply chains must navigate 27 different major privacy frameworks on average.

- Algorithmic bias can perpetuate or amplify existing inequities in supplier selection, with a recent Stanford study finding that unconstrained AI procurement systems favored larger, established suppliers by a margin of 3.5:1 over smaller or minority-owned businesses.

Cybersecurity vulnerabilities increase as supply chains become more digitized and AI-dependent. The World Economic Forum reports that AI-managed supply chains experienced 47% more cyberattack attempts in 2024 than traditional systems, requiring substantial security investments.

DocShipper Alert

Struggling with AI implementation for your logistics operations? DocShipper’s specialists help you overcome the biggest hurdles—from data integration to workforce training—with proven methodologies that have delivered successful AI transformations for companies just like yours. Our phased approach breaks complex projects into manageable steps with clear ROI at each stage. Schedule a no-obligation consultation with a DocShipper expert today

AI Applications Across the Supply Chain Ecosystem

Artificial intelligence is delivering value across every stage of the supply chain, from sourcing and procurement through to final customer delivery and service.

Let’s discover how you can implement AI and automation within each step of the supply chain processes and operations to harness its total potential and optimize your logistics operations.

1. Procurement and Supplier Management

AI has revolutionized how organizations identify, evaluate, and collaborate with suppliers:

- Intelligent Vendor Selection: AI systems now evaluate thousands of potential suppliers against dozens of criteria simultaneously, analyzing elements like financial stability, ESG performance, and production capabilities to identify optimal partners.

- Automated Contract Intelligence: Advanced NLP systems review supplier agreements to identify savings opportunities, ensure compliance, and even conduct routine negotiations without human intervention.

- Supply Chain Transparency: AI monitoring tools track environmental and social metrics across extended supplier networks, using satellite imagery, social media analysis, and public records to verify sustainability claims.

- AI Warehouse Automation: Revolutionizing Inventory Management. AI warehouse automation has emerged as a critical technology in modern logistics, enabling unprecedented levels of efficiency and precision

Our AI-powered logistics platform demonstrates how intelligent systems can transform traditional warehouse operations.Key aspects of AI warehouse automation include:- Intelligent robot coordination

- Real-time inventory tracking

- Predictive stock management

- Automated picking and sorting systems

Our AI-driven supplier evaluation system processes over 10,000 potential manufacturing partners across Asia, identifying optimal matches for client requirements 75% faster than traditional methods while reducing procurement costs by an average of 12%.

DocShipper Innovation:

Our AI-driven supplier evaluation system processes over 10,000 potential manufacturing partners across Asia, identifying optimal matches for client requirements 75% faster than traditional methods while reducing procurement costs by an average of 12%.

Pierre Rahmé- Cheif Operation Officer & Co founder of DocShipper Group

2. Warehouse and Inventory Management

Smart warehouse operations have evolved beyond simple automation to create facilities that continuously adapt to changing conditions:

- Collaborative Robotics: Advanced vision systems enable robots to work safely alongside humans, handling repetitive tasks while adapting to dynamic environments.

- Dynamic Inventory Optimization: AI algorithms adjust stock levels in real-time based on hyperlocal demand patterns, reducing capital requirements while improving product availability.

- Predictive Space Utilization: Digital simulations identify optimal warehouse layouts and continuously reconfigure storage locations based on forecasted order patterns.

- AI-Driven Door-to-Door Solutions: These advancements extend beyond the warehouse, with AI optimizing the entire shipping process to provide seamless door-to-door delivery and comprehensive logistics support.

DocShipper info

Automate your door-to-door shipping with our smart, door-to-door solutions. Our DocShipper AI-powered processes ensure seamless logistics and expert support from origin to destination. Need simplified, automated shipping?

3. Transportation and Logistics Optimization

AI is changing logistics & supply chain but has also transformed transportation networks into dynamically adapting systems that maximize efficiency:

- Continuous Route Recalculation: Modern logistics platforms evaluate thousands of potential delivery sequences hourly, adapting to traffic, weather, and new orders in real-time.

- Autonomous Transportation: Self-driving vehicles and drones have moved beyond experiments to handling specific operational segments with remarkable efficiency and safety.

Capacity Marketplaces: AI matching platforms connect shippers with available transportation capacity, reducing empty miles by 45% while cutting carbon emissions significantly. This process has upgraded AI logistics operations 360° during 2024, 2025 but also the upcoming years.

DocShipper Advice

Our AI transportation platform analyzes over 2,000 global shipping routes daily, delivering an average 22% reduction in transit times and 15% decrease in shipping costs compared to traditional methods in 2024.

Ready to transform your supply chain with AI-powered optimization? Contact our experts today

4. Customer Experience and Service Enhancement

AI has revolutionized customer interactions through personalization and proactive service:

- Tailored Delivery Experiences: Advanced algorithms predict ideal delivery windows and methods for each customer, increasing first-attempt success while improving satisfaction.

- Anticipatory Support: AI systems identify potential delivery issues before they occur, enabling proactive communication that transforms potential failures into demonstrations of competence.

Simplified Returns: Intelligent systems determine optimal disposition paths for returned items, increasing recovery value while improving the customer experience.

Emerging AI Trends in 2025 and beyond applied to the Supply Chain field

The supply chain landscape is experiencing unprecedented technological evolution as AI is changing logistics & supply chain and its capabilities continue to advance rapidly. Forward-thinking organizations are deploying increasingly sophisticated AI solutions that transcend traditional analytics to deliver transformative operational advantages.

These emerging technologies promise to redefine industry standards for efficiency, resilience, and innovation across global supply networks. Let’s dive into the new AI trends :

Trend 1 : Generative AI Applications

Generative AI has moved beyond creative applications to deliver substantial business value:

- Network Design Optimization: These systems explore thousands of potential supply chain configurations, identifying non-obvious arrangements that simultaneously improve cost, service, and sustainability metrics.

- Autonomous Planning: Generative AI creates and refines operational plans without human intervention, continuously evaluating alternatives to optimize for changing conditions.

- Synthetic Data Generation: AI creates realistic simulations of rare events like disruptions or new product launches, enabling organizations to prepare for situations they’ve never encountered.

Trend 2 : AI-Powered Digital Twins

AI is changing logistics & supply chain, thus digital replicas have evolved from static models to dynamic systems that continuously simulate and optimize physical supply chains:

- Real-Time Replication: Modern twins maintain perfect synchronization with physical operations, incorporating data from thousands of sensors to identify bottlenecks before they impact performance.

- Scenario Testing: These platforms safely evaluate complex “what-if” scenarios, predicting the impact of potential disruptions and policy changes before implementation.

- Autonomous Implementation: Leading digital twins now directly execute optimizations, adjusting production schedules, inventory policies, and transportation plans without human intervention.

DocShipper info

Our sophisticated simulation of global logistics operations predicts shipping delays with 87% accuracy up to 9 days in advance, allowing proactive implementation of mitigation strategies before our clients’ shipments are affected. Contact our team today to implement predictive logistics solutions for your business

Trend 3: Edge AI and IoT Integration

The influence of AI on logistics and supply chain demonstrates that edge computing combined with AI enables intelligent operation even in challenging connectivity environments:

- Decentralized Intelligence: Processing at the edge allows continuous monitoring and decision-making regardless of network availability, particularly valuable in remote transportation contexts.

- Responsive Automation: Edge AI enables sub-millisecond responses to changing conditions, critical for coordinating autonomous vehicles and robotics in dynamic environments.

- Resilient Operations: These systems continue functioning during connectivity disruptions, maintaining operational continuity despite challenging conditions.

Case Studies: AI Success Stories in Supply Chain

1. Maersk's AI-Driven Shipping Network

Implementation Case:

Maersk, the global shipping leader, implemented an AI-driven Remote Container Management (RCM) system to transform their international shipping operations.

The solution combines IoT sensors on refrigerated containers with advanced machine learning algorithms that monitor temperature, humidity, and CO₂ levels in real-time.

When anomalies are detected, the system automatically triggers alerts and recommends corrective actions. Additionally, Maersk deployed the “Captain Peter” virtual assistant that provides customers with container tracking visibility and proactive notifications about potential delays, using natural language processing to answer customer inquiries without human intervention.

Benefits & Statistics:

- 60% reduction in refrigerated cargo spoilage through predictive maintenance

- Vessel fuel consumption decreased by 12%, saving $150M annually

- Customer service inquiries reduced by 25% through automated tracking assistance

- 30% improvement in container utilization rates

- Carbon emissions reduced by 5% through AI-optimized routing

Major Takeaways:

- Real-time data analytics enabled shift from reactive to proactive logistics management

- Integration of IoT with AI created significant operational and environmental benefits

- Customer experience improved through transparent, AI-powered communication

Key Considerations:

- Success required retrofitting existing container fleet with compatible sensors

- Data standardization across global operations was a prerequisite for implementation

- Significant staff retraining was necessary to maximize system effectiveness

2. Amazon's End-to-End AI Integration

Implementation Case:

Amazon implemented multi-layered AI systems across their entire supply chain ecosystem. At the procurement level, they deployed adaptive learning algorithms that analyze historical sales data, seasonal trends, and even competitor pricing to optimize inventory levels.

In fulfillment centers, computer vision systems guide robots that transport shelves of products to human pickers, while AI determines optimal item placement based on order frequency and relationships between products. For last-mile delivery, dynamic routing algorithms process driver locations, traffic patterns, package characteristics, and delivery windows in real-time, continuously recalculating optimal routes as conditions change.

Benefits & Statistics:

- $1 billion annual inventory cost reduction through AI-driven demand forecasting

- 50% increase in warehouse picking efficiency with computer vision systems

- 99.99% order accuracy with AI-guided fulfillment

- 30% faster delivery times through dynamic routing algorithms

- 65% reduction in out-of-stock situations

Major Takeaways:

- Comprehensive AI integration across all supply chain functions creates multiplicative efficiency gains

- Machine learning continuously improves from massive operational data feedback loops

- AI deployment transformed logistics from a cost center to competitive advantage

Key Considerations:

- Success required deep integration between AI systems and physical infrastructure

- Significant investment in computing power and specialized AI talent was necessary

- Continuous improvement philosophy essential for ongoing optimization

Unilever's Demand Forecasting Revolution

Implementation Case:

Unilever implemented an AI-powered demand sensing platform that transformed their traditional forecasting approach across their vast product portfolio.

The system integrates point-of-sale data, weather patterns, local events, social media trends, and competitor promotions to predict consumer demand with unprecedented accuracy.

Their implementation features a digital twin of their entire supply network that runs continuous simulations to identify potential disruptions before they occur. At manufacturing facilities, machine learning algorithms optimize production scheduling based on these forecasts, while automatically adjusting for capacity constraints, material availability, and energy costs.

Benefits & Statistics:

- 30% reduction in forecast error rates across product portfolio

- 15% decrease in required safety stock levels

- 20% improvement in on-shelf availability

- $300M annual savings in inventory holding costs

- 40% faster response to sudden demand pattern changes

Major Takeaways:

- Integration of unconventional data sources dramatically improved forecasting accuracy

- Digital twin simulations enabled proactive scenario planning and risk mitigation

- AI-based forecasting successfully scaled across diverse markets and product categories

Key Considerations:

- Implementation required breaking down data silos between departments

- Models needed continuous refinement to account for regional market differences

Clear visualization of AI insights proved essential for human decision-maker adoption

DocShipper's AI-Driven Route Optimization: Revolutionizing Supply Chain Efficiency

At DocShipper, AI isn’t just a feature—it’s the core of our vision. We’ve placed artificial intelligence at the heart of our supply chain operations, transforming how global trade happens.

Our mission is simple:

“leverage cutting-edge AI to make logistics smarter, faster, and more efficient for our clients.” – DocShipper Founders

Our AI-powered approach spans three critical areas:

Intelligent Sourcing & Procurement

- AI-driven supplier matching

- Predictive cost and quality analysis

- Real-time market intelligence

- Automated vendor evaluation

Comprehensive Logistics & Freight Forwarding

- Dynamic route optimization

- Predictive shipping time calculations

- Automated customs documentation

- Easier freight forwarder evaluation and connection

- Real-time tracking and risk management

- End-to-end door-to-door intelligence

Holistic Supply Chain Transformation

- Continuous performance optimization

- Data-driven decision support

- Adaptive logistics strategies

- Sustainable and cost-effective solutions

When global shipping complexities threatened to overwhelm our clients, we realized AI was the key to transforming logistics.

Our breakthrough came by reimagining route optimization—not just as a technical challenge, but as a way to solve real business problems.

By leveraging AI, we’ve turned shipping routes from fixed paths into intelligent, adaptive networks.

Our platform now predicts optimal routes in real-time, cutting delivery times by 30% and reducing transportation costs by 22%.

This is how AI is changing logistics & supply chain at DocShipper premises: turning inefficiency into opportunity, one shipment at a time.

The Future of AI in Logistics and Supply Chain

Emerging Technologies on the Horizon

- Quantum Computing: These systems promise to solve previously intractable routing and allocation problems 100x faster than classical approaches, with early pilots showing potential cost savings of 15-22%.

- Augmented Reality Integration: AR technologies enhance human capabilities across logistics operations, improving accuracy to 99.9% while increasing productivity by 25% and reducing training requirements.

Advanced Natural Language Processing: Conversational interfaces allow stakeholders to interact with complex systems using everyday language, democratizing access to supply chain intelligence.

Ethical AI and Responsible Implementation

As AI systems become increasingly autonomous, ethical considerations take on greater importance:

- Transparency and Explainability : Leading organizations now provide human-readable justifications for automated decisions, maintaining complete audit trails of AI recommendations and implementations.

- Fairness Safeguards and Bias Prevention: Regular bias audits ensure algorithms don’t systematically disadvantage specific suppliers or customers, with corrective mechanisms to address unintended consequences.

- Environmental Sustainability : AI optimization now explicitly considers carbon footprint alongside traditional metrics, reducing emissions while improving efficiency.

Through responsible development and deployment, organizations can ensure that AI advances benefit all supply chain stakeholders while addressing critical sustainability challenges facing our global logistics networks.

Conclusion

The integration of AI into logistics and supply chain operations has transformed from a competitive advantage to an essential business requirement in 2025. Organizations implementing AI strategies are experiencing significant improvements in operational efficiency, forecasting accuracy, and risk management capabilities, with industry leaders like Maersk, Amazon, and Unilever demonstrating concrete ROI through reduced costs and enhanced service levels.

While challenges remain – from implementation costs to data quality issues – the path forward is clear. Companies that strategically embrace AI while addressing these challenges will thrive, while those that hesitate risk falling behind more agile competitors.

At DocShipper, we remain committed to leading this AI revolution in logistics, continuously enhancing our capabilities to deliver unprecedented speed, accuracy, and cost-effectiveness to our clients.

By combining cutting-edge AI technologies with deep logistics expertise, we’re helping organizations navigate today’s complex supply chains while positioning them for success in tomorrow’s increasingly AI-powered world.

FAQ :How AI is Changing Logistics and Supply Chain in 2025 ?

AI implementation delivers multiple benefits across supply chain operations, including operational efficiency gains (predictive maintenance reducing downtime by 20-30%, automated decision-making cutting planning time by up to 90%), enhanced forecasting accuracy (reducing forecast errors by 30-40% while lowering safety stock requirements), and improved risk management capabilities (detecting disruptions days or weeks before they impact operations). These improvements translate directly to bottom-line benefits, with documented cost reductions of 10-20% alongside service level improvements of 15-25% across multiple industry leaders.

Organizations implementing AI face four primary challenges: (1) Financial barriers, with enterprise-grade AI platforms costing $500,000-$2.5 million and 62% of initiatives exceeding budgets; (2) Data quality issues, with companies spending 60-70% of project budgets on data preparation rather than AI algorithms; (3) Workforce adaptation challenges, with 72% of failed implementations citing employee resistance as the primary cause; and (4) Ethical considerations including transparency, privacy, and algorithmic bias. Companies that invest in proper data governance, change management, and ethical frameworks report substantially higher success rates.

Industry leaders are implementing AI across all supply chain functions. Maersk uses IoT sensors and machine learning to monitor container conditions in real-time, reducing cargo spoilage by 60% and fuel consumption by 12%. Amazon deploys multi-layered AI systems across procurement, warehousing, and delivery operations, increasing picking efficiency by 50% while reducing inventory costs by $1 billion annually. Unilever's AI-powered demand sensing platform integrates unconventional data sources like weather patterns and social media trends, reducing forecast errors by 30% and saving $300 million in inventory costs. These comprehensive approaches create multiplicative efficiency gains that transform logistics from cost centers to competitive advantages.

Several transformative technologies are poised to further revolutionize logistics operations. Quantum computing systems promise to solve complex routing and allocation problems 100x faster than classical approaches, with potential cost savings of 15-22%. Augmented reality technologies enhance human capabilities throughout logistics operations, improving accuracy to 99.9% while increasing productivity by 25%. Advanced natural language processing allows stakeholders to interact with complex systems using everyday language, democratizing access to supply chain intelligence. Companies that proactively explore these emerging technologies position themselves at the forefront of the ongoing AI revolution in logistics and supply chain management.

Read More

Looking for more? These articles might interest you:

Need Help with Logistics or Sourcing ?

First, we secure the right products from the right suppliers at the right price by managing the sourcing process from start to finish. Then, we simplify your shipping experience - from pickup to final delivery - ensuring any product, anywhere, is delivered at highly competitive prices.

Fill the Form

Prefer email? Send us your inquiry, and we’ll get back to you as soon as possible.

Contact us